Signs do more than point directions—they share your style, promote ideas, or add fun to spaces. This guide shows you how to make custom signs with easy steps.

You learn materials, designs, and tools that fit your needs. Whether for home, business, or events, you can create them yourself or sell online.

Get ready to turn simple ideas into standout pieces. Let's start.

8 Custom Sign Materials You Should Know About

Wood Signs

You go for wood when aiming for a cozy, natural setup. Rustic styles shine in cabins, coffee shops, or outdoor weddings—hand-painted or carved details add a personal touch.

Seal it well for gardens or porches to last 5–7 years without warping. Avoid thin cuts in windy areas; they split easily.

Custom Round Wooden Door Sign (Made in USA) - Print-On-Demand - PrintKK

Glass Signs

Glass brings quiet class. Etched or frosted suits high-end hotels or boutiques; LED-backlit adds glow to evening venues.

Temper it for safety in public spots. Limit to indoors—weight makes it tricky outside—and wipe with soft cloths to stop scratches.

Metal Signs

Metal holds up in tough conditions. Aluminum suits lightweight outdoor needs like storefronts or parks, while steel or brass works for engraved industrial looks.

Powder-coat it to fight rust—expect 10+ years. Place it high to dodge scratches in busy areas.

Custom Printed on Demand Metal Signs Outdoor 11.8"x7.9" - Daily Accessories - PrintKK

PVC / Foam Board Signs

These keep things light and easy. PVC handles indoor/outdoor tradeshows or menu boards well, while foam board stays inside for quick displays.

Both cut into shapes for fun events. Skip foam in rain—it warps fast—but PVC lasts months outside if mounted flat.

Acrylic Signs

Acrylic gives a sleek, modern edge. Clear or frosted fits office lobbies or retail displays; backlit versions pop in low-light bars or events.

Use UV-treated sheets outdoors under cover to prevent yellowing after a few years. Clean gently to keep the shine without marks.

Print on Demand Acrylic Window Hanging Ornament - Home Decor - PrintKK

Vinyl Signs

Vinyl sticks anywhere flexible. Stickers or wall decals fit home offices or shops; banners work for festivals or vehicles.

Choose weatherproof types for outdoor use up to 3–5 years. Apply with air-release backing to avoid bubbles on curves.

Chalkboard / Whiteboard Signs

These allow easy changes. Reusable chalkboards fit casual cafes or classrooms with a decorative, vintage feel; whiteboards suit offices for notes.

Magnetic ones hold extras like pins. Keep indoors—sun fades the surface quickly—and erase fully to avoid ghosts.

Fabric / Canvas Signs

Fabric rolls up for travel. Banners or flags suit pop-up markets or weddings with a soft, artistic vibe. Dye-printed polyester holds colors well indoors or under tents.

Hang taut to prevent sags in wind, and store flat to reuse often.

Custom Garden Flag 12"x18" (Made in USA) - Print on Demand Fulfillment - PrintKK

How to Make Your Own Custom Signs

Sign Goals & Location

Before you begin to do more or ask what kind of sign will be required, think about what its function must be. Are you trying to sell things, point the way, or simply decorate?

Find the ideal spot for it to hang. Measure off the space and note the distance at which it will be seen.

Then tailor an appropriate size, font, and material for your sign so that it can actually help those who see it.

Choose Both Material and Size

Consider the weather, cost, and look you're after.

For outdoor use you can't go wrong with metal or weather-resistant PVC. For indoor use, choose from among acrylic, glass, or foam board.

Here is an easy method to remember: the greater the viewing distance, the larger your letters should be.

If a person had to stand 30 ft away in order to see them, then his lettering would need to have 3 in high letters, roughly.

Choose a material to match your sign's longevity.

Designing for Readability and Effect

Use short sentences in high contrast. Use single strong messages and large letters vertically set in clear fonts.

Do not use fonts with a connected script for very long words. Only use simple icons if they help explain the message.

Once your design is finished, preview it at the same size as actual in real time on screen, or make a small mock-up so that you can quickly see whether people will be able to read it.

Print On Demand Rectangular Tin Sign Metal Sign Decor 12"x8" (Horizontal) - PrintKK

Keep Press-Ready Files

Export clean files for the printer. For logos and sharp edges, use vector files so lines stay sharp at any size.

If you must use images, save them at 300 dpi for close viewing. Add bleed and secure margins so no part gets cut off.

Provide clear file names and, when you load them up, an abbreviated note to say material and size.

Print-On-Demand for Low Risk

If you want to sell signs or try new designs with only a small inventory, do use POD services. They print and mail each set of orders. This saves you from mass costs and storage space.

Make sure the POD supplier provides material samples and proofs. Before they sell, have them send you a first sample so you can double-check color, size, and finish.

Build and Hang Carefully

If you make the sign yourself, use the right tools: clamps, proper fasteners, and weatherproof glue or caulking. Sand and seal wood, and use rust-resistant screws for all metal.

For hanging, match the mount type to the wall type — plastic anchors for drywall, lag bolts for studs in load-bearing walls, special adhesives for glass. Do a final check on alignment and stability before leaving it at that.

Test and Maintain After Installation

Inspect your sign after several days and again after one month, and see if it is beginning to fade, if there are any loose screws, or any water damage.

Clean it gently and touch up any paint or caulking as required. If your sign is lit, check that wiring and lamps function well on a regular basis.

This is a good time for small repairs that will keep your sign looking good for years to come.

Tips to Create Eye-Catching Custom Signs

Know Your Audience First

Think about who will see the sign. Drivers need big, simple text they can read fast from far away. Shoppers inside might like more detail and fun details.

Match the style and words to fit their age, speed, and what grabs them right away. This keeps your sign useful instead of ignored.

Keep the Message Short and Clear

Stick to one main idea per sign. Use no more than 7-10 words if it's for quick glances. Too much text blurs together when people pass by. Focus on the key point, like your business name or a special offer, so it sticks in their mind.

Choose Fonts That Read Easily

Pick simple, bold fonts like sans-serif ones. Avoid fancy or thin letters that get hard to see from a distance. Make the main words much larger than extras.

Test sizes by standing back—your text should feel clear even when you're moving past it.

Use Strong Color Contrast

Pick colors that stand out against each other, like dark text on a light background or the reverse. Bright combos catch eyes better than soft ones.

Avoid colors that blend into the surroundings, such as a green sign in a tree-filled spot. Good contrast makes everything pop.

Leave Plenty of Blank Space

Aim for about 40% empty space on your sign. This gives the text and images room to breathe. Crowded designs look messy and hard to read.

Blank areas guide the eye straight to what matters most and make the whole thing feel clean.

Match Colors to Your Brand and Goal

Stick with your usual brand colors for recognition. Bright shades work well for fun or kid-focused spots. Calmer tones suit professional services.

Test how colors look in different lights—daylight and night—to ensure they stay visible and appealing.

Think About Where the Sign Will Go

Placement changes everything. Roadside signs need huge letters and bold designs. Indoor ones can use finer details.

Check viewing distance and angle ahead of time. This helps you pick the right size, material, and layout so the sign works in its real spot.

Test Your Design Before You Print

Print a small version or view it on screen from far away. Ask a few people what they see first and if they get the message quick.

Small tweaks now save headaches later. Simple changes in size or color can turn an okay sign into one that really stands out.

Custom Tin Sign Rectangular (2:3) Metal Sign Decor (Vertical) - Print-On-Demand - PrintKK

Choose Sign-Making Tools Based on Budget and Skill

Check Your Skill Level First

Look at if you are a beginner with little time, someone in the middle, or ready for pro work. New hands start with easy stuff like hand tools or free apps such as Inkscape and Canva.

Pros jump to complex machines. Factor in hours you have each week. This match stops frustration and waste.

Set a Budget That Makes Sense

Go low with DIY under $300 like print-on-demand from Printify at $12 per sign or basic vinyl cutters around $200.

Mid-range hits $1,000 to $5,000 for tools that pay back over time with repeat jobs. Skip big spends if you test one-offs first. Track costs for supplies too.

Beginners Stick to Simple, Cheap Tools

Grab hand tools, router jigs like Milescraft SignPro for $80, or entry vinyl cutters from Cricut Explore at $250.

Pair with free software like Inkscape for vectors or Silhouette Studio. These cut wood or vinyl without a learning curve. Good for home or small runs indoors.

Intermediate or Pros Need Stronger Gear

Step up to laser cutters from $2,500 like xTool or CO2 models for acrylic and wood. CNC routers start at $7,000 for metal signs.

Use paid software such as Easy Cut Studio at $60 or SAi Flexi monthly. These handle details and speed for shops or events.

Line Tools up with Your Goals

One custom sign? Use print services or basic cutters that match wood or vinyl. Lots of orders? Get gear for high output like lasers on multiple materials.

Check if it fits your volume and spots like outdoors. This keeps quality high without extra buys.

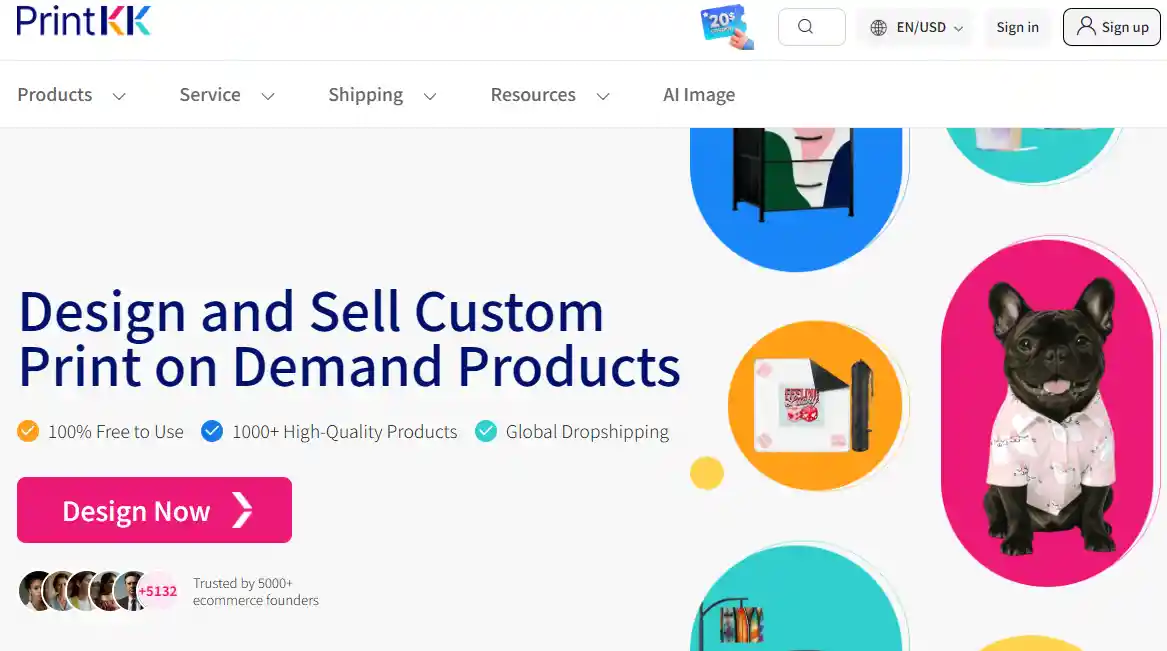

Make and Sell Custom Signs Online With PrintKK

You can start making custom signs fast with PrintKK. Just sign up for free on their site, jump into the design tool, upload your artwork or create something new, pick your sign type, and place your order. You can buy one sample or order in bulk for discount prices that drop as you add more.

PrintKK ships to the US without any extra taxes or duties, which keeps your costs low. Their signs come at good quality for the price. You get options like metal signs for tough outdoor use, canvas for soft wall art, and acrylic for that shiny indoor look.

They also have an AI image tool to fix up your designs quickly—turn rough ideas into sharp, print-ready files in minutes.

You connect PrintKK easily to your stores on Etsy, Shopify, or Amazon. Orders sync automatically, they print and ship straight to your buyers, and you focus on selling.

Expert Tips

You have come far in this guide. You now know how to make custom signs from start to finish. Pick materials that fit your needs. Design with care for clear looks. Make them at home or use online tools. Sell them to share your work.

Get creative. Try new ideas. You will enjoy the results. Start small and build up. Your signs can brighten spaces.

FAQs

How much does it cost to make a custom sign?

Prices start around $15 for small vinyl or foam signs. Larger metal or acrylic ones run $50 to $200. Bulk orders drop the price per sign. Your design complexity and material choice affect the final cost.

What is the best material for custom signs?

It depends on your needs. Metal lasts longest outdoors. Acrylic looks modern and clear indoors. Wood gives a warm feel for rustic styles. Pick what matches your location and look.

Can I use my own logo or artwork for custom signs?

Yes, you can upload your own logo or artwork. Most services accept personal files. This makes your sign unique and matches your brand perfectly.

What file format is best for printing signs?

Use vector files like AI, EPS, or SVG for sharp results at any size. High-resolution PNG or JPEG works too if you keep them at 300 DPI or higher.

How long does it take to get custom signs delivered?

Most orders take 5 to 10 business days from approval to delivery. Rush options cut it to 2 or 3 days. Shipping time adds 3 to 7 days depending on your location.

What is the best size for a sign?

The right size fits where you place it and who sees it. Roadside signs need 4x8 feet or bigger. Indoor ones work well at 2x3 feet or smaller. Think about viewing distance first.

Global Shipping

Global Shipping

Made in USA

Made in USA