Printing custom shirts can seem straightforward until you start comparing methods, materials and order sizes—each of which influences the final price.

If you've ever wondered how much does it cost to print a shirt, understanding these key factors makes budgeting far easier.

From print techniques to garment quality, this guide breaks down the elements that shape your total cost so you can choose the right option for your project or business.

How Much Does It Cost to Print a Shirt

1. Type of Printing Method Matters

The cost of printing a shirt changes a lot depending on the printing method. Screen printing is usually cheaper if you order many shirts, but setup costs can make small batches expensive.

DTG Printing works best for detailed designs or tiny orders, but it costs more per shirt.

You should think about how many shirts you need and how detailed your design is before choosing a method. Picking the right method can save you both time and money.

Print On Demand Men's Combed Cotton Short-Sleeved T-Shirt - PrintKK

2. Number of Colors in Your Design

Each color in your design usually adds extra cost. Screen printing adds a separate screen for each color, which increases setup fees.

Even DTG can take longer with more colors, raising production time. If your design has many shades or gradients, the price can go up fast.

You can simplify your design colors or use fewer shades to keep the cost reasonable without losing the look of your design.

3. Shirt Quality and Fabric

The kind of shirt you pick makes a big difference. Basic cotton shirts are usually cheaper, while tri-blends, organic cotton, or moisture-wicking fabrics cost more.

Thicker fabrics can also be slightly pricier because they use more material. Think about your audience—if you want a premium look, you might pay more, but if you just need a casual shirt, standard fabrics work fine.

Picking the right balance between quality and cost helps you get the best value.

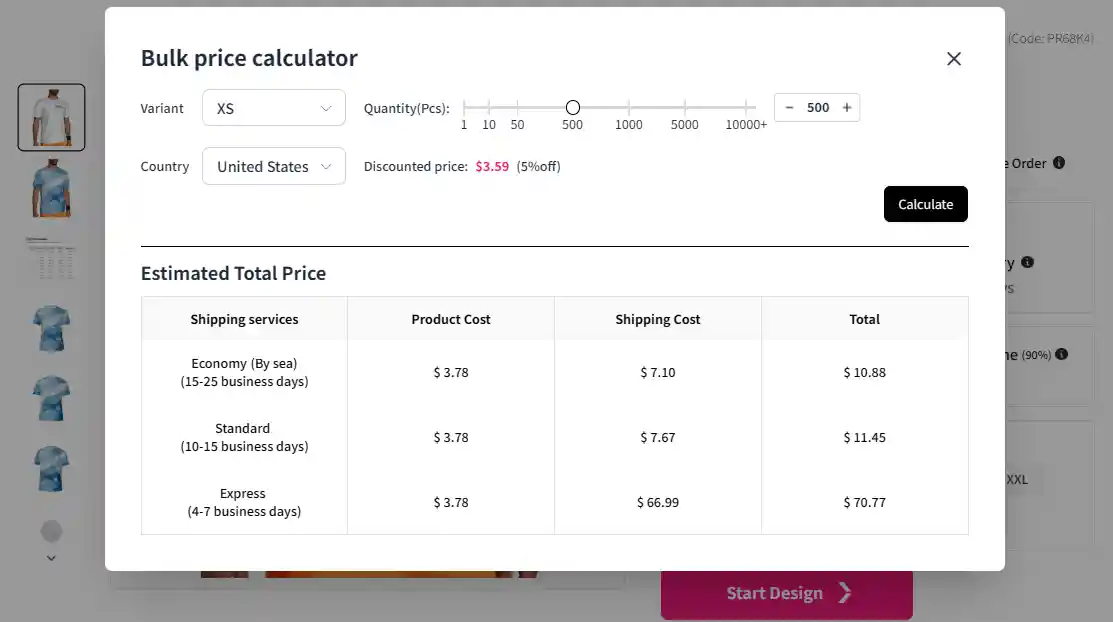

4. Order Size Can Change Your Price

Ordering more shirts usually lowers the cost per shirt because setup fees get spread over a bigger batch.

Small orders may have higher per-unit costs since setup fees stay the same. For example, printing 5 shirts might cost $12 each, but printing 50 could drop the cost to $6 each.

You can also plan for a few extra shirts for giveaways or mistakes, which saves money in the long run. Always check if the printer offers bulk discounts.

5. Additional Factors That Add Up

Other details can quietly increase your total cost. Printing on sleeves, back, or inside the collar usually costs extra.

Rush orders or tight deadlines often raise prices significantly. Some printers also charge extra for custom artwork cleanup or unusual sizes. Asking for a full quote upfront and clarifying these extra fees helps you avoid surprises.

Planning ahead and knowing what each fee covers keeps your budget in control.

Is It Cheaper to Print Shirts Yourself or Outsource?

Deciding between printing shirts yourself and outsourcing depends on more than just cost. Buying a printer and all the supplies might look cheaper over time, but the reality can be different.

If you print on your own:

- Learning the process takes time and materials, and early mistakes can quickly increase costs.

- You are responsible for all equipment, maintenance, and supplies, which can become a hidden expense.

- Managing production on top of running your business can take away focus from other important tasks.

Outsourcing the printing:

- Frees up your time so you can concentrate on design, marketing, and growing your brand.

- Minimizes wasted shirts from trial-and-error, especially when testing new designs.

- Ensures professional-quality results without needing to master a new skill.

For most new brands, starting with a professional printer is more practical. Once operations are running smoothly and designs are proven, printing your own shirts can be revisited without the pressure of mistakes affecting your business.

Hidden Shirt Printing Costs and How to Avoid Them

Setup Fees

Setup fees cover the work needed before printing starts. For screen printing, this means making screens; for digital printing, it's prepping the files.

If you're printing multiple shirts with the same design, ordering in bulk helps. It spreads the fee over more shirts and lowers the cost for each one. Planning ahead can make a big difference.

Color Separation Fees

Each color in a design can increase time, materials, and cost. Extra screens or specialty inks add up quickly. You can manage costs by:

- Limiting designs to 1–2 colors for small batches

- Sticking to standard inks instead of special effects like metallic or glow-in-the-dark

- Testing a single shirt before placing a large order

Simpler designs don't just save money—they also reduce mistakes.

Artwork Cleanup Charges

Low-resolution or non-vector files often need fixing, which can add extra charges. Providing high-quality vector files from the start avoids surprises.

Double-check your design before submitting so you don't spend time or money on corrections later.

Mixed Size or Split Order Fees

Printing different sizes or multiple garment types can increase handling and packaging costs. To minimize extra charges:

- Keep sizes consistent when possible

- Group similar garments together

- Ask for a full quote upfront if you need variety

This approach helps you avoid unexpected fees and keeps your per-shirt cost predictable.

Rush Production Fees

If you need shirts quickly, printers usually charge more. Same-day or urgent orders can double or triple your cost.

Planning even a few days ahead can save you a lot. Submitting orders early gives flexibility and keeps prices reasonable.

Extra Print Locations

Adding prints to sleeves, the back, or inside the collar increases setup and ink costs. Most of the time, a single front print is enough. If you want multiple locations, limit them to special orders or premium shirts to justify the extra cost.

Why Choose Print on Demand, and How Much Does It Cost?

Why Choose Print on Demand

If you want to start selling shirts without tying up a lot of money in inventory, print on demand (POD) is a practical option.

With POD, you upload your design, and the provider handles printing and shipping only when an order comes in. That means you don't end up with boxes of unsold shirts sitting around.

Here's why POD can make a difference:

- Lower upfront cost: You only pay when someone buys a shirt.

- Flexibility to experiment: You can try multiple designs without committing to large orders.

- Less operational work: No packing, shipping, or managing stock.

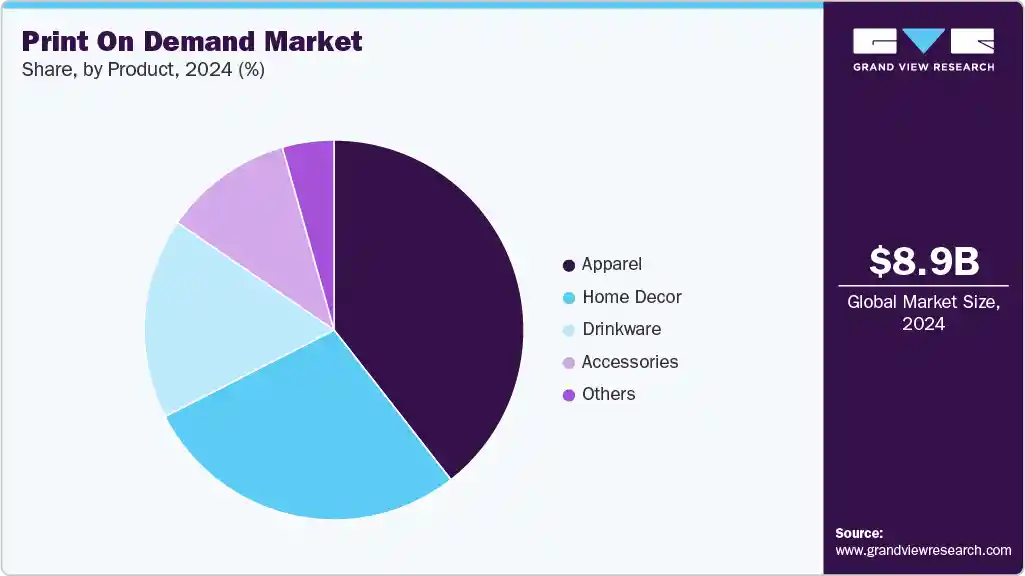

The numbers show why it's popular. In 2024, the global print-on-demand market is expected to reach $8.93 billion, and apparel holds the largest share, around 40%.

This means a lot of creators are finding POD a reliable way to start and grow a shirt business.

How Much Does It Cost?

The cost per shirt depends on the shirt type, printing method, and platform. A simple cotton t-shirt usually costs $8–$15 to produce, while premium shirts or more detailed designs can reach $20 or more. Shipping fees vary depending on your customer's location.

One practical point is that the production cost is separate from your selling price. Most POD platforms let you set the retail price yourself, which lets you control your profit.

Choosing POD is often more about reducing risk and testing ideas than finding the absolute cheapest option.

Read More:

- How to Make a T-Shirt Business Plan

- How Much is the T-shirt Printing Business Start-Up Cost? The Cheapest Way

Start Your Custom T-Shirt Business With PrintKK

Getting started with PrintKK is simple. You can design your T-shirt directly on their platform and place an order in just a few clicks.

Upload your artwork or use their tools, choose your shirt style, and select the sizes you need. The whole process is fast and beginner-friendly.

One of the biggest advantages of using PrintKK is the cost savings. T-shirts shipped to the US don't carry seller taxes, and their products are both affordable and high-quality.

This makes them perfect whether you want to buy for yourself, give as gifts, or sell to customers.

PrintKK offers a wide range of options:

- Men's, women's, and youth T-shirts

- Plus-size shirts

- Various colors and styles

Custom Printed on Demand Zip Polo Shirts for Men Relaxed Fit (AOP) - PrintKK

Their AI Image tool helps you enhance your existing designs or create new ones quickly. Even if you're new to T-shirt design, you can start producing professional-looking shirts without a steep learning curve.

Expert Tips

Now you know the main factors that affect how much does it cost to print a shirt. The price depends on the printing method, shirt quality, design complexity, order size, and extra fees. You can plan smarter by understanding each cost factor.

Always check for hidden fees, compare methods, and choose the right shirt type for your needs. Small changes in your design or order can save money.

By paying attention to these details, you can control costs and make better decisions. Understanding the full picture helps you budget well and get the most value from every shirt. You are now ready to move forward with confidence.

FAQs

What is the average cost for screen printing a single shirt?

Screen printing a single shirt usually costs more than bulk orders. Prices generally range from $10 to $25 depending on colors, shirt quality, and setup fees, making small orders pricier per unit.

How much do people charge for a shirt design?

Charges for a shirt design vary by complexity and designer experience. Simple designs may cost $20–$50, while detailed or custom illustrations can reach $100 or more, depending on revisions and usage rights.

How much profit can one make on a shirt?

Profit depends on your cost per shirt and your selling price. Many sellers aim for $5–$15 profit per shirt, but it varies with order size, printing method, and pricing strategy.

What are the most economical printing methods for t-shirts?

Screen printing is often cheapest for large runs, while heat transfer or DTG can be better for small orders. Choosing the right method based on quantity and design keeps your costs low.

Can I design my own t-shirt online?

Yes! Online platforms let you upload images, add text, or use templates to create shirts easily. You can adjust colors and placement, making it simple even if you're new to design.

Global Shipping

Global Shipping

Made in USA

Made in USA