Business gets busier during the shopping season. This means more packages, tighter delivery deadlines, and greater pressure to deliver on time.

These holiday shipping tips will assist you in preparing for the increased volume. They cover planning, carrier selection, packing, setting deadlines, and keeping costs low.

By using these tips, you will minimize delays and stress, improving customer satisfaction. The aim is simple: make the holiday season smoother than before.

Let's get into it and see what works based on experience.

15 Holiday Shipping Tips for Managing Seasonal Demand

Plan Your Shipping Early

You should start thinking about the holidays in July or August—seriously. Pull last year's order numbers, spot the crazy spikes (usually Black Friday through Dec 20), then call your carriers.

Ask: "What volume are you expecting? Any rate hikes coming? Can we lock in capacity early?" Getting that conversation done early can save you from "sorry, we're at capacity" messages more than once. The earlier you lock things in, the less you pay in panic fees later.

Forecast Demand—Don't Guess

Don't rely on gut feelings. Export last December's sales by day, layer on this year's site traffic trends, check Google Trends for your top categories, and see what competitors are pushing. This tells you which SKUs will explode in demand.

Then adjust inventory buys and tell your warehouse team exactly how many extra packers you'll need the week of Dec 15. Good forecasting means you rarely stock out on winners or sit on piles of losers in January.

Stock Up on Packaging Way Ahead

Nothing kills momentum like running out of boxes at 3 p.m. on Dec 18. Order 2–3× what you think you'll need for tape, labels, bubble wrap, and void fill by early October. Keep a "panic stash" of 500 extra flat-rate boxes in a corner.

When volume triples overnight, you can still pack at full speed instead of hunting for supplies on Amazon at double price.

Print On Demand Black Shoe Box - PrintKK

Put Real Deadlines Everywhere

Vague "order by Dec 20 for Christmas" copy frustrates customers. List exact dates on every product page, cart page, and checkout: "Last day for standard ground to arrive by Dec 25: Dec 15." Show countdown timers near the holidays.

Your customers plan better, you get fewer "where's my order?" tickets, and returns from disappointed buyers drop noticeably.

Never Bet on One Carrier

Relying on a single company is risky. Keep active accounts with UPS, FedEx, and USPS (sometimes regional carriers too). Mid-December one year, UPS volume surcharges spiked 40% overnight—you can quietly shift 60% of packages to FedEx and USPS and avoid a huge hit.

Relationships matter: the account reps who know you move volume year-round are the ones who pick up the phone and find space when everyone else is full.

Use Inventory Tools That Give You Real-Time Visibility

You run one dashboard that pulls stock from every channel—Shopify, Amazon, your site. Low-stock alerts ping you instantly so you reorder before you're out. During peak, you check velocity reports daily to see what's exploding.

That stops you from selling things you can't ship and lets you shift marketing to the real winners.

Prep Your Team Before the Storm

You hire temps and add shifts in October, not mid-December. Quick training on packing, labeling, and quality checks. You set a clear daily plan—who picks, who packs, who handles the late surge. A trained team that knows the rhythm moves faster and screws up less when orders triple.

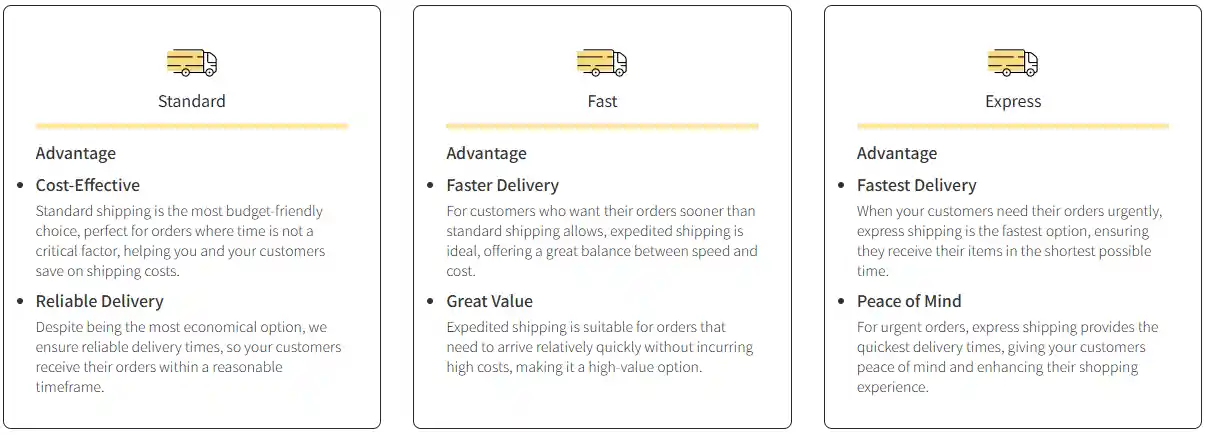

Give Customers Real Shipping Choices

Let people pick between cheap-and-slow (ground), middle (2-day), and hero-mode (next-day or Saturday where available).

You can also set a free-shipping threshold that's a little higher during peak—it nudges average order value up and lets you batch more packages together.

When someone chooses ground in early December, your warehouse breathes easier; when they pay for 2-day on Dec 20, you still hit the delivery promise.

Rearrange Your Warehouse for Speed

Every November you move the top holiday SKUs right next to packing stations—no long walks. You group similar items and label bins big and clear.

Those tweaks cut pick time in half. When you're doing hundreds more orders a day, seconds saved per package add up to hours and let you ship more without extra people.

Communicate Clearly with Customers

Send instant order confirmation emails, shipping notifications, and tracking links. If delays happen because of weather or carrier volume, tell customers early with an honest update.

Clear, timely communication builds trust, lowers the number of "where is my order" support requests, and improves overall satisfaction.

Simplify Your Packaging Process

Standardize box sizes for common order types and use the least amount of material needed for safe shipping. Pre-assemble frequently used box sizes.

Simpler processes reduce packing time per order and help avoid higher dimensional weight fees that carriers charge during peak season.

Monitor Carrier Performance Daily

Check on-time delivery rates, scan issues, and any reported exceptions every day during the holidays. Reach out to your carrier contacts immediately if you notice problems starting.

Quick action fixes small issues before they affect large numbers of packages and keeps most deliveries on schedule.

Plan for Returns Early

Publish a clear holiday return policy with extended deadlines if possible. Set up an easy online return portal and prepare return labels in advance.

Staff up for reverse logistics after the holidays so returned items do not pile up and slow down new order processing.

Negotiate Rates Ahead of Time

Reach out to carriers several months before peak season to discuss volume commitments and lock in better base rates.

Ask about avoiding or reducing holiday surcharges. Negotiating early often saves significant money when peak season fees hit every package.

Test Your Full Process Before the Rush

In October, run several test orders from start to finish: place the order, pick and pack it, apply labels, hand it to the carrier, and track it. Look for bottlenecks or errors in any step.

Fix problems early so your real holiday orders flow smoothly when volume surges.

How to Choose the Right Shipping Option

Speed Usually Trumps Everything Else

If the customer orders after mid-December, ground shipping almost always arrives too late. "2–5 business days" turns into a week or more with holiday volume.

You should switch to 2-day or next-day right away. The higher price is worth avoiding angry messages and refund requests. For early-month orders, ground still works and keeps costs down.

Match the Carrier to What You're Shipping

Anything under 4 pounds? USPS Priority Mail or flat-rate boxes usually beat UPS and FedEx on price for most destinations.

Heavier or bulkier packages? UPS Ground or FedEx Home Delivery often come out cheaper. Keep a quick reference of last season's rates for your common sizes so you don't waste time comparing every single order.

Where It's Going Changes the Math

Big cities get ground fast and inexpensive. Rural areas, Alaska, or Hawaii? Ground can take forever and cost more than expected.

Add extra days and often bump those to Priority or air service. Also warn customers at checkout about longer times for remote spots. They will appreciate the honesty way more than a missed deadline.

Cost vs. Peace of Mind

Saving a few dollars on ground makes sense for cheap items. For anything valuable or fragile, pay extra for reliability with stronger tracking and fewer lost-package stories.

One bad experience with a high-value return costs far more than the savings from ten cheap shipments. Pick reliability when it matters.

Give Customers Clear Choices at Checkout

Show three options: the cheapest (slowest), a middle one, and the fastest. Next to each, list a realistic arrival date based on when you'll actually ship.

Customers pick what fits their needs, and you get fewer "where is it" tickets because they understood the trade-offs from the start.

Holiday Shipping Deadlines in the US

You should know these dates in order to ship your packages in time for the major holidays in 2026. Remember, it's always best to verify with your shipping services, like USPS, UPS, or FedEx, closer to the date, as these dates may vary. Here's a general guide for the major dates.

Valentine's Day (February 14, 2026)

A short, sharp gift rush.

- Standard ground (2–5 business days): Ship by February 6.

- 2-day / expedited: Ship by February 10.

- Next-day: Ship by February 12–13.

Mother's Day (May 10, 2026)

Very last-minute heavy.

- Standard ground: Ship by May 2.

- Expedited: Ship by May 7.

- Next-day: Ship by May 9.

Father's Day (June 21, 2026)

Same tight window as Mother's Day.

- Standard ground: Ship by June 13.

- Expedited: Ship by June 18.

- Next-day: Ship by June 20.

Thanksgiving (November 26, 2026)

Kicks off the big holiday volume spike.

- Standard ground: Ship by November 17.

- Expedited: Ship by November 21.

- Next-day: Ship by November 24–25.

Christmas (December 25, 2026)

The peak everyone plans around.

- Standard ground: Ship by December 15–17.

- Priority / 2–3 day: Ship by December 19–20.

- 2-day air: Ship by December 22.

- Overnight: Ship by December 23 (for Dec 24 delivery in many areas).

- Alaska, Hawaii, and rural ZIPs often need 2–4 extra days.

New Year's Eve / Day (December 31, 2026 – January 1, 2027)

Many carriers pause or slow on Jan 1.

- Standard ground: Ship by December 29 for early Jan arrival.

- Expedited: Ship by December 30.

- Next-day: Some options available December 31.

Read More:

Reducing Shipping Fees During Peak Holiday Season

Know the Surcharges and Watch for Them

Every year carriers add peak surcharges, fuel fees, and charges for big or heavy packages. These extra costs can add up fast during November and December.

Look at your past holiday shipments to see which ones triggered the highest fees. Once you spot the patterns—like certain sizes or delivery dates—you can plan around them. Knowing the rules ahead of time helps you avoid surprise charges.

Talk to Your Carriers and Ask for Better Deals

If you ship a good amount of packages, carriers often listen. Reach out early and ask about temporary waivers or caps on peak fees. You can also bundle services or promise steady volume to get lower base rates.

Even small improvements make a difference when you multiply them across hundreds of orders. Strong relationships pay off during busy times.

Pack Smarter to Shrink Dimensional Weight

Dimensional weight (DIM) charges hit when boxes are large but light. Switch to smaller boxes, mailers, or flexible pouches whenever possible. This simple change often drops your costs right away.

You can also combine orders when it makes sense or spread shipments across quieter days. Better packing and timing keep more packages in lower rate categories.

Let Software and Other Options Do the Work

Good shipping software compares rates in seconds and selects the least expensive route for each package. You should use it for every shipment. Another option is to consider regional carriers, parcel lockers, or pickup locations in high-traffic areas.

These services are often less expensive than home delivery. Using a mix of shipping methods can help you avoid the highest holiday rates while ensuring your packages are delivered on time.

Print on Demand 3-Pack Gift Wrapping Paper Sheets - Daily Accessories - PrintKK

Practical Tips to Avoid Package Disasters

Ship Earlier Than the Carrier's Deadline

If the shipping company says December 20 is the cutoff for on-time delivery, try to get your packages out by early December instead.

This gives you extra time to handle surprises like bad weather, truck problems, or extra volume on busy routes. Packages headed to the West Coast often face more delays this time of year, so sending them out sooner helps a lot.

Fill Every Bit of Empty Space Inside the Box

Empty space lets items shift around and crash into each other during transit. Pack tightly so nothing moves. Use bubble wrap, packing paper, or air pillows to fill gaps.

Double-bag any liquids to stop leaks. One leaking bottle can ruin your package and delay others in the sorting process.

Pack Breakable Items to Survive Rough Handling

Shipping facilities move boxes fast. Packages slide down chutes, drop onto conveyor belts, and get stacked or tossed. Wrap fragile things well so they can handle the weight of heavier boxes landing on top.

Test your packing by imagining it has to take up to 70 pounds of pressure if you use USPS. Strong packing means fewer broken items and unhappy customers.

Use Plenty of the Right Tape

Tape every seam on the box. Extra tape adds protection against other packages rubbing or pressing against yours. Go over the main flaps and sides.

Avoid duct tape or painter's tape—they peel off easily and cause problems. For heavy boxes, run tape strips perpendicular to the main seam. This spreads out the stress and keeps the box closed tight.

Expert Tips

You've got a solid set of tools now. These holiday shipping tips cover everything from early planning to smart packing, clear deadlines, and cost control.

Start sooner. Communicate better. Choose wisely. Stay flexible.

When you put these steps in place, the busy season feels less chaotic. Orders ship on time. Customers smile. Your team stays calm.

You can handle 2026 with confidence. Go make this holiday season your smoothest one yet. You've got this.

Global Shipping

Global Shipping