Printing your own mugs can be fun and rewarding. Whether you want to sell them or make personalized gifts, choosing the right method matters. Different techniques give different results in quality, durability, and style.

In this guide, you'll learn about the main methods of printing mugs, their pros and cons, and how to pick the best one for your needs. By the end, you'll feel confident to start creating mugs that look great and last long.

7 Popular Methods of Printing Mugs

Screen Printing

Screen printing pushes ink through a fine mesh stencil onto the mug. You hold the mug in a jig or cylinder press and spread the ink evenly.

After that, the ink is cured using heat or UV light, making the print stick permanently.

- Best Surfaces: Works on smooth ceramic or glass mugs. Rough surfaces or uncoated metals may not hold the ink properly, causing smudging or poor adhesion.

- Durability: Prints are thick and resistant to scratches, fading, and normal dishwasher use if cured properly. Solid colors last well, making it a great choice for logos or designs that need to withstand heavy handling.

- Look & Feel: Bold designs, text, and logos look sharp. Screen printing is not ideal for detailed photos or subtle color gradients, but you can layer inks for effects like metallic or glow-in-the-dark.

- Tips: Multi-color designs require careful registration. Clean your screens after each batch to maintain crisp edges. Start with small runs to test your process before scaling up.

Sublimation Printing

Sublimation printing uses special dye inks that turn into gas under heat and bond with a coated mug.

You print your design on sublimation paper, tape it securely around the mug, and press it in a heat press or oven.

The heat and pressure allow the dye to penetrate the coating, making the design part of the surface rather than just sitting on top.

- Best Surfaces: Works only on polyester or polymer-coated mugs. Regular ceramic or glass won't hold the design. If you try sublimating on uncoated mugs, the design will fade or scratch off quickly.

- Durability: Prints are highly resistant to fading, peeling, or cracking. Many premium coated mugs can survive thousands of dishwasher cycles. For long-term use, avoid abrasive scrubbing or harsh chemicals.

- Look & Feel: Colors are bright, gradients are smooth, and the surface stays perfectly flat. Photo wraps and detailed patterns come out crisp, and the design feels integrated into the mug, not layered on top.

- Tips: Test your press temperature and time, always use heat-resistant tape to avoid smudges, and choose high-quality coated blanks.

Print on Demand Color Changing Mug (11oz) - Drinkware - PrintKK

Pad Printing

Pad printing uses a soft silicone pad to pick up ink from an engraved plate and press it onto curved surfaces.

This method lets you print small logos or text precisely, even near handles or other awkward areas.

- Best Surfaces: Works well on most ceramic mugs and some curved glass mugs. Ideal for logos, small text, and simple graphics. Complex photo designs are not suitable.

- Durability: Prints last a long time when the surface is properly prepped. Cleaning and priming the mug before printing improves ink adhesion and longevity.

- Look & Feel: Clean, sharp, and precise for small designs. The ink layer is slightly raised, giving a tactile feel without being intrusive.

- Tips: Great for medium-volume production. Monitor the silicone pads for wear and ensure ink is evenly distributed for consistent results.

Decal Printing (Water Transfer / Ceramic Decals)

Decal printing involves printing designs on special decal paper, applying them to the mug, and firing them in a kiln.

The image fuses with the glaze, producing smooth, permanent designs, including detailed photos and gradients.

- Best Surfaces: Smooth ceramic mugs or glass with appropriate coatings. A kiln is required, so it's less practical for home setups.

- Durability: Extremely durable. Properly fired decals are dishwasher-safe and can survive microwaves without damage. Designs last for years without fading.

- Look & Feel: Can reproduce photos, detailed patterns, and gradients perfectly. The design becomes part of the mug, creating a smooth, professional finish.

- Tips: Trim decals carefully to avoid overlaps or air bubbles. Test-fire a small batch before full production. Handle decals gently when wet to prevent smearing.

UV Printing

UV printing uses ultraviolet light to cure ink directly onto the mug. Some systems print to a transfer film first, then apply it.

The method works on coated ceramics, glass, or metal for full-color, durable designs.

- Best Surfaces: Works on coated ceramics, metals, and glass. Can print on both dark and light surfaces.

- Durability: Prints are durable, but long-term dishwasher safety depends on the ink and curing process. Testing batches is essential.

- Look & Feel: Full-color designs are possible, including detailed images. Some prints have a slightly raised texture. Smooth surfaces look clean, and colors remain vibrant.

- Tips: Use a primer or pre-coating for better adhesion. Ideal for small businesses due to quick setup. Test each substrate type to ensure consistent results.

Custom Glass Tumbler with Straw & Bamboo Lid (16oz) - Print on Demand Fulfillment - PrintKK

Laser Engraving

Laser engraving burns or etches the design into the mug's coating or glaze. The laser removes the top layer, leaving a permanent mark with sharp, clean lines, ideal for logos or high-end, minimalist designs.

- Best Surfaces: Works on coated ceramics, painted mugs, stainless steel, and glass. Cannot engrave uncoated or rough mugs effectively.

- Durability: Extremely long-lasting. No ink to fade or peel. Designs can survive heavy use, dishwashers, and microwaves if the surface is properly prepared.

- Look & Feel: Produces high-end, minimalist designs in monochrome. Lines are sharp and crisp, perfect for logos or premium gifts.

- Tips: Works only in single color. Ensure proper ventilation when engraving and keep laser settings precise. Slower than other methods, so batch production may take longer.

Heat Transfer & Vinyl Transfers

Heat transfer printing uses printable paper or vinyl sheets applied with a heat press.

The design melts or activates the adhesive, sticking to the mug surface temporarily or semi-permanently, making it perfect for small batches or one-off gifts.

- Best Surfaces: Works on coated ceramic mugs and polymer-coated blanks.

- Durability: Prints can peel over time, especially in high-heat dishwashers. Hand washing is recommended for longevity.

- Look & Feel: Suitable for photos, text, and simple graphics. A thin film layer covers the surface, slightly raised but not intrusive.

- Tips: Ideal for single gifts, prototypes, or very small runs. Correct temperature, pressure, and quality transfer materials are key to a smooth finish. Test small batches first to avoid mistakes.

How to Judge the Quality of a Ceramic Mug?

When you want to evaluate a ceramic mug, you can use three simple senses: look, listen, and touch. Each step helps you spot whether the mug is well-made or not.

1. Look at the Mug

Start by examining its appearance and texture. A quality mug has:

- A smooth, even glaze

- Consistent color across the body

- A rim that is perfectly shaped, without deformation

Check the handle: it should be straight and securely attached. Avoid mugs with tilted handles or visible glaze shrinkage at the joint — these are signs of poor craftsmanship.

Hold the mug up to sunlight; a good ceramic mug should show a slight translucency, which indicates proper firing.

2. Listen to the Sound

Tap the mug gently with your finger. A high-quality mug produces a crisp, clear "ding" sound. A dull or muffled tone may indicate mixed or low-quality materials.

Check the sound where the lid (if any) meets the body. A subtle echo or crisp connection confirms solid construction. This simple step helps you assess material quality without any tools.

3. Touch and Feel the Surface

Run your hand over the mug's body. A well-made mug should feel smooth and flawless, without pinholes or bumps.

Inspect the bottom as well — there should be no sticky marks or glaze defects caused by poor firing. These tactile checks ensure the mug is both safe and pleasant to use.

Custom Large Colorful Mug (15oz) (Made in USA) - Print-On-Demand - PrintKK

How to Overcome the Challenges of Printing on Mugs?

1. Handling Screen Printing Challenges

Screen printing on mugs is tricky, especially around the handle or on curved surfaces. The key is using the right equipment and ink. If you have a cylinder printer, start there.

Use inks that can be properly cured—like kiln-fired inks, UV inks, or inks with a catalyst. You'll also need a special screen frame to print around the handle.

A practical tip: practice on a few test mugs before committing to a full batch. This helps you adjust your technique without wasting materials.

2. Controlling Shipping and Costs

Shipping mugs can get expensive, especially for small batches. To overcome this, consider batching orders or combining shipments to reduce per-mug costs.

Another option is to work with a fulfillment partner or a supplier who ships in bulk. That way, you don't lose clients due to high shipping fees.

For personal projects, plan ahead and be realistic about how many mugs you can afford to send at once.

3. Choosing the Right Printing Method

Different printing methods have pros and cons. Sublimation is simple but can fade and usually requires handwashing. UV printing is sharper and easier but the image is slightly raised.

To overcome this, match the method to your needs: use sublimation if you want smooth prints for gifts, and UV printing if you want durability and don't mind a raised design.

4. Business vs. Personal Projects

If you're printing mugs as a business, small-batch orders usually have much lower profit margins compared to bulk production.

Shipping and material costs take up a big part of your price, so it's hard to compete with suppliers who buy in containers.

One way to overcome this is to use a Print on Demand (POD) service. With POD, you can offer customized mugs without holding inventory, and the service handles shipping directly to your customers.

What's the Best Method of Printing Mugs for You?

DIY Lovers – For Hobbyists and Personal Projects

If you love making things at home, sublimation printing or heat transfer printing is perfect for you. These methods are easy to learn and don't need expensive machines. You can print small batches without worrying about wasting materials. A few tips:

- Use high-quality sublimation paper for brighter colors.

- Make sure your mug is coated for sublimation.

- Heat transfer works well if you want to try fun designs with stickers or iron-on sheets.

Both methods let you get creative. You can experiment with different designs, fonts, and colors without a big investment. Even a beginner can make something that looks professional.

Small Business Owners – For Quick Orders

If you're running a small mug business, UV printing can be a game-changer. You don't need a kiln, and the colors pop beautifully. It's low-maintenance and fast, which is ideal if you're taking small orders online or at local markets.

What makes it great for small businesses:

- Prints are durable and water-resistant.

- No long drying times, so you can ship faster.

- Works well on a variety of mug shapes and surfaces.

Using this method lets you keep costs low while maintaining a professional look. Your customers will appreciate the quality, and you can scale slowly without buying huge machines.

Large-Scale Manufacturers – For Big Production Runs

If your goal is to produce mugs in large quantities, screen printing or decal printing with kiln firing is your best bet.

These methods are reliable and produce consistent results, even in thousands of units. The colors stay sharp, and the prints can handle dishwashing without fading.

Key advantages:

- Perfect for large batch production.

- Long-lasting designs for repeated use.

- Can combine multiple colors and effects.

It's a bit more complex than DIY methods, but the efficiency and durability make it worthwhile for factories and bulk production.

Custom Standard Colorful Coffee Mug (11oz) (Made in USA) - Print-On-Demand - PrintKK

Premium / Gift Market – For High-End Custom Mugs

If you want to sell mugs as luxury gifts, consider laser engraving or decal printing with kiln firing.

Laser engraving gives a sleek, permanent design, while kiln-fired decals add a delicate, polished look. Both methods make your mugs feel special.

Why this works for premium items:

- Adds a tactile, high-quality feel.

- Designs are long-lasting and won't peel.

- Excellent for small, personalized orders with intricate details.

These methods let you stand out in a crowded gift market. A carefully engraved mug feels like a keepsake, and beautifully fired decals can compete with boutique brands.

Print-on-Demand Sellers – For Flexible E-Commerce

If you run an online store, your priority is flexibility and low inventory risk. Sublimation or UV DTF printing works best here. You can produce mugs only when a customer orders, avoiding storage costs.

Important points for POD sellers:

- Choose methods that are easy to ship without damage.

- Quick turnaround keeps your customers happy.

- Focus on color accuracy and design clarity to minimize returns.

By using on-demand printing, you can test new designs, offer seasonal specials, and keep your offerings fresh without locking in a lot of stock.

PrintKK Helps You Start a Profitable Mug Business

Starting your own mug business can feel overwhelming, but PrintKK makes it surprisingly simple.

You can quickly set up a store and integrate it with popular platforms without any complicated steps.

Once your store is connected, you're ready to start adding products and designs that reflect your style or niche.

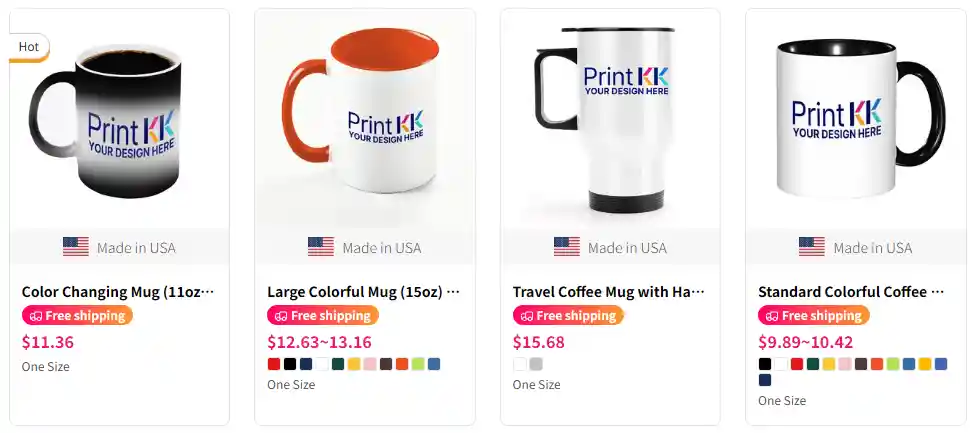

One of the biggest advantages of using PrintKK is the cost and shipping benefits. For example:

- Products shipped to the US don't charge sellers any extra tax.

- Made in US mugs come with free shipping, which means you can keep more profit from every sale.

PrintKK also gives you plenty of options to make your mugs stand out. You can choose from:

Designing your mugs doesn't have to be hard either. PrintKK's AI Image tool lets you quickly create new designs or improve the ones you already have. Even if you're new, you can start making eye-catching mugs in no time.

With PrintKK handling the tricky parts, like shipping and production, you can focus on designing, marketing, and growing your brand. It's a solid way to turn your creative ideas into a profitable mug business without getting stuck in complicated processes.

Read More:

Expert Tips

Choosing the right method of printing mugs can make a big difference for your business or hobby. You have several options, and each has its own strengths.

By understanding the process, you can save time and money. You can also produce mugs that look professional and last long.

Focus on what works best for you. Keep experimenting and learning. Over time, you'll find a method that fits your style and needs.

With the right approach, printing mugs can be simple, fun, and rewarding.

FAQs

Which Method Is Best for Mug Printing?

The best method depends on your needs. Some methods suit small batches, others work for large orders. Consider quality, durability, and cost to pick the one that fits your goals.

What Do You Need to Start a Mug Printing Business?

To start, you need basic equipment, blank mugs, and design tools. You also need a platform to sell and a clear plan. Skills in design and marketing help, but you can learn as you go.

How Much Does It Cost to Print a Mug?

Costs vary by method, materials, and quantity. On average, it includes the mug, ink, and production. Keep in mind shipping and packaging if you plan to sell. Calculating all helps set fair prices.

Is Selling Custom Mugs Profitable?

Yes, it can be profitable with good planning. Profit depends on pricing, cost control, and demand. Unique or well-designed mugs often sell faster, and managing orders efficiently keeps profits higher.

Made in USA

Made in USA

Global Shipping

Global Shipping