When it comes to printing custom T-shirts, the choice between silk screen vs heat transfer can shape not just the look of your design, but how long it lasts and how it feels on the fabric.

Silk screen has a reputation for durability and bold colors, while heat transfer offers flexibility for small runs and complex designs. Knowing the strengths and limitations of each method can save time, money, and frustration down the road.

This article dives into what actually matters in real-life projects, so you can pick the method that fits your needs rather than just following trends.

How Does a Silk Screen Work?

Silk screen printing, also called screen printing, uses a stencil and a mesh screen to apply ink directly onto the fabric.

The key principle is forcing ink through the open areas of the stencil while keeping the rest blocked. Here's how it works step by step:

- Create the stencil: Design your image and block out the parts that should not get ink.

- Set up the screen: Place the mesh screen over the T-shirt.

- Apply the ink: Use a squeegee to push ink through the open areas of the screen.

- Layer and dry: Repeat for multiple colors if needed, then let the ink dry or cure.

Silk screen is different from heat transfer because you apply the ink directly to the shirt, which gives a textured feel and strong durability.

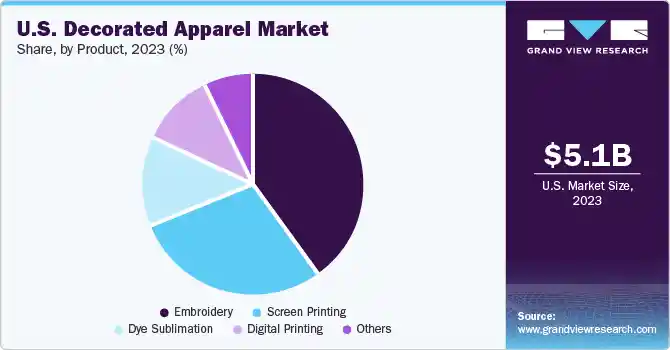

In fact, in the US Decorated Apparel Market, silk screen is the second-largest printing method, showing its popularity and reliability.

Understanding this process helps you know why the design lasts long and how vibrant the colors can appear on different fabrics.

How Does a Heat Transfer Work?

With heat transfer, you start with a printed design on special transfer paper or vinyl.

The key principle is applying heat and pressure to move the design onto the fabric. Here's how it works step by step:

- Prepare the design: Print it on transfer paper or cut it from heat transfer vinyl.

- Apply heat and pressure: Use a heat press or iron to activate the adhesive layer.

- Bond to the fabric: Pressure ensures the design sticks evenly without gaps or wrinkles.

- Cool and set: Let the transfer cool so the design fully adheres to the shirt.

Heat transfer differs from methods that put ink directly on the shirt. You're transferring a ready-made image, which works well for detailed, full-color designs.

Understanding these steps helps you know what to expect in durability, texture, and appearance.

Silk Screen vs. Heat Transfer: Detailed Comparison

Printing Process

Silk Screen

Silk screen printing pushes ink through a fine mesh onto your T-shirt. Each color needs a separate screen, so multi-color designs take more steps.

You control ink thickness by how much you press. Screens must be prepared carefully to avoid leaks. The process works best when you have flat surfaces. It is slower for complex images, but the ink layers are thick and solid.

Heat Transfer

Heat transfer printing first puts your design on paper or film. Then heat and pressure transfer the image to the shirt.

You can print multiple colors and even photographs in one step.

The process is faster for detailed or small-batch designs. It works on flat and curved surfaces with the right setup. However, the print sits on top of the fabric rather than soaking in like silk screen.

Custom Men's Short-Sleeve Button-Down Shirt - Print on Demand Fulfillment - PrintKK

Print Quality & Detail

Silk Screen

Silk screen gives bold and vibrant colors that stand out.

It is excellent for logos and simple graphics. Fine lines smaller than 0.3mm may blur if your mesh count is low.

Gradients are difficult because each color layer must be applied separately. You can adjust ink thickness for texture, but extreme details may not transfer well.

Overall, silk screen is strong for clear, solid designs but less flexible for photographic images.

Heat Transfer

Heat transfer can produce high-resolution and photorealistic designs. Gradients, shadows, and tiny details stay crisp.

You can print full-color images without worrying about layering colors. The print looks smooth and flat on the shirt.

However, the ink layer is thinner, so the feel of the fabric can be different. Heat transfer works well for complex images but may not have the thick texture that silk screen provides.

Durability

Silk Screen

Silk screen prints are very durable. The thick ink sticks well to fibers and can withstand many washes.

You can print on cotton, polyester, and blends, and the design is less likely to peel or crack. Proper curing improves life span.

If you take care of the T-shirt, your print may last for years. Durability is one of the main reasons factories still choose silk screen for long-lasting designs.

Heat Transfer

Heat transfer prints are softer and feel closer to the fabric. They can fade or crack over repeated washing, especially if heat or pressure was insufficient during transfer.

You can improve durability with proper technique, but long-term wear is less reliable than silk screen. For casual or short-term use, heat transfer works fine, but for heavy-duty apparel, it may need extra care.

Cost & Efficiency

Silk Screen

Silk screen has higher setup costs. Each color needs a screen, and making screens takes time. Small orders can be expensive because you spend the same effort for fewer shirts.

Large batches reduce cost per shirt, making silk screen efficient for hundreds or thousands of prints.

If you plan multiple runs, screens can be reused, which saves time later. The upfront effort is worth it for high-volume orders.

Heat Transfer

Heat transfer is cheaper for small orders because you don't need to make screens. Each design can be printed immediately.

You can easily produce one shirt or hundreds with minimal setup. For complex, colorful designs, it is more efficient than silk screen for small batches.

Large orders are possible but slower and more labor-intensive per shirt than silk screen.

Custom Men's Mesh T-Shirt - Print on Demand Fulfillment - PrintKK

Design Flexibility

Silk Screen

Silk screen works best with bold shapes and limited colors. Adding more colors requires more screens and careful registration.

Fine details and gradients are harder to print. You can adjust ink thickness or layer textures, but changing designs mid-run is slow.

Silk screen is less flexible if you often switch graphics, but it excels for consistent, repeated designs.

Heat Transfer

Heat transfer can handle any design you want. Photos, gradients, and complex graphics are easy. Changing the design takes no extra time.

You can print multiple colors in one pass. This makes it ideal for custom shirts or personalized orders. However, the print layer is thinner, so texture options are limited compared to silk screen.

Material Compatibility

Silk Screen

Silk screen works on many fabrics: cotton, polyester, and blends. Special surfaces may require ink or stencil adjustments.

You can print on flat or slightly curved surfaces, and even on wood, plastic, or metal with the right ink. It is versatile but may need different setups for each material. Proper mesh and ink selection are key to consistent results.

Heat Transfer

Heat transfer works best on polyester or light-colored fabrics. Dark fabrics need special opaque inks or films.

You can print on mugs, metal, or plastic using compatible transfer sheets. The technique is limited by material heat tolerance, since the process relies on heat to transfer the image.

Some fabrics may scorch if temperature isn't correct.

Custom AOP Hawaiian Shirt for Men with Print on Demand - PrintKK

Environmental Impact

Silk Screen

Silk screen uses water and chemicals for screen cleaning. Improper disposal can pollute water sources.

Eco-friendly or water-based inks reduce impact, but you still generate wastewater.

Large operations need filtration or treatment systems. Consider ink choice and cleaning process if environmental regulations matter.

Heat Transfer

Heat transfer uses little water and produces minimal chemical waste. Some inks are eco-friendly and non-toxic. However, you consume electricity with heat presses.

Overall, it is cleaner than traditional silk screen for small or medium production, but energy use should be monitored.

Order Volume Suitability

Silk Screen

Silk screen is best suited for medium to large batches. You save cost per shirt when printing hundreds or thousands, because screens can be reused and setup cost is spread over many shirts.

Small runs are inefficient since making screens takes time and effort. If you frequently produce the same designs, silk screen becomes very efficient and reliable.

It works less well for on-demand or highly personalized orders.

Heat Transfer

Heat transfer is ideal for small batches or customized shirts.

You can print one shirt at a time without extra setup, making it perfect for personalized or seasonal orders.

Large orders are possible, but the process can be slower per shirt compared to silk screen. Heat transfer shines when you need flexibility, quick changes, or multiple designs in a short time.

It's less cost-effective for very high-volume production.

How to Choose the Right Mesh Count for Screen Printing

Choosing the right mesh count is critical for the quality of your print.

The mesh affects how much ink passes through the screen, how sharp the design looks, and how durable the print will be. Picking the wrong mesh can make a good design look blurry or uneven.

What Is Mesh Count?

Mesh count is the number of threads per inch on the screen. Common examples are 110, 160, and 230. Higher mesh counts have thinner threads and smaller openings, while lower mesh counts have thicker threads and larger openings.

- Low mesh count → larger openings, more ink passes through.

- High mesh count → smaller openings, finer detail but less ink flow.

How Mesh Count Affects Printing Results

Print Detail: Higher mesh gives sharper edges and finer lines.

Ink Flow: Lower mesh lets thicker layers of ink pass, ideal for bold prints.

Color Density: Low mesh gives stronger coverage.

Durability and Registration: Proper tension helps with alignment and wear.

Matching Mesh Count with Ink Type and Particle Size

The ink particles must be smaller than the mesh openings.

- Glitter or metallic ink → low mesh (60–90).

- Plastisol or standard textile ink → medium mesh (110–160).

- Water-based or UV ink for fine detail → high mesh (180–230+).

Choosing Mesh Count by Design Type

Design Type | Recommended Mesh Count | Notes |

Bold logos / thick prints | 80–110 | Better ink coverage |

Standard graphics / T-shirts | 120–160 | Balanced choice |

Fine text / gradients / halftones | 180–230+ | High precision |

Metallic / glitter inks | 60–90 | Larger openings prevent clogging |

Common Mistakes and Troubleshooting

- Choosing mesh too high → ink won't pass through.

- Choosing mesh too low → design looks thick or blurry.

- Ignoring ink viscosity or stencil thickness.

- Not keeping screen tension properly.

Why Is Heat Transfer Printing Becoming Popular?

Heat transfer printing has gained popularity because it addresses the limitations of silk screen printing in modern production. When your design is complex, silk screen requires a separate screen for each color.

This creates two main problems: fine details can blur, and color registration often shifts, making gradients and intricate patterns difficult to achieve.

Heat transfer solves this by applying the entire design at once, preserving detail and smooth color transitions.

Small batch orders also favor heat transfer. Silk screen involves significant setup time and cost for screens, which only makes sense for large quantities.

With heat transfer, you can print even a hundred items without creating new screens, reducing both cost and lead time.

Environmental factors contribute as well. Silk screen uses large amounts of water and generates chemical waste, while heat transfer minimizes water usage and pollution.

Heat transfer is not replacing silk screen entirely but provides a better fit for current market needs. It allows you to produce detailed, small-batch, and environmentally friendly prints efficiently.

Which Printing Technique Is Better for T-Shirts?

1. Designing for Your Small Business

If you run a small T-shirt business and often change designs, heat transfer might be more flexible for you.

You can print single items quickly without waiting for screens.

It works well when you experiment with different colors or detailed graphics. Silk screen is better when you know the design will be repeated many times.

2. Making Team or Event Shirts

When you need matching shirts for a team or event, silk screen printing is often more cost-effective.

Once the screens are ready, you can print dozens of shirts quickly.

The prints are durable and stand up to repeated washing, which is useful if the shirts will be worn multiple times.

Custom AOP Football Jersey with Print on Demand - PrintKK

3. Personal Gifts and Custom Shirts

If you want a one-of-a-kind gift or personalized shirt, heat transfer lets you print complex images, photos, or gradients easily.

You don't need to invest in screens, and you can produce a small number of shirts without high setup costs. Silk screen can feel excessive for just one or two items.

4. Everyday Wear and Long-Term Durability

When you care about how long a shirt will last under regular wear, silk screen prints have an advantage.

The ink bonds well with the fabric, resisting fading and cracking. Heat transfer designs may show wear faster, especially if you wash shirts frequently or use hot water and dryers often.

5. Creative and Colorful Designs

If you enjoy experimenting with full-color or detailed designs, heat transfer offers more freedom. You can include photos, gradients, and tiny details without extra cost.

Silk screen can produce bold colors and simple graphics well, but it becomes complicated and expensive with many colors or intricate patterns.

Expert Tips

Choosing between silk screen vs heat transfer depends on your needs.

If you want bold, durable prints and work with large runs, silk screen is strong and reliable.

If you need detailed designs, gradients, or small batches, heat transfer gives more flexibility and faster turnaround.

Understanding these differences helps you make the right choice for your T-shirts. Focus on what matters most for your project. With the right method, you can achieve high-quality prints that last and look professional.

FAQs

How long does a silk screen last?

A silk screen can last for years if cared for properly. The ink bonds strongly with the fabric, resisting fading and cracking through repeated washes, making it reliable for shirts you plan to wear often.

What lasts longer, screen printing or heat press?

Screen printing generally lasts longer. The ink is absorbed into the fabric, creating a durable design. Heat press prints can fade, peel, or crack faster, especially if washed frequently or handled roughly over time.

Which printing method is more cost-effective for small orders?

For small batches, heat transfer is usually more practical. You don't need to create multiple screens, which keeps setup costs low. Silk screen becomes cheaper only when printing larger quantities of shirts.

Can heat transfer print on dark fabrics?

Yes, but it requires special transfer materials. Standard transfers may appear dull or not show properly. Using opaque or white-backed transfers helps designs stand out clearly on darker fabrics.

What is better, DTF or silk screen?

DTF (Direct-to-Film) works well for detailed, full-color prints and small runs. Silk screen excels at bold, simple designs and large orders. The best choice depends on your design complexity and quantity needs.

Global Shipping

Global Shipping